FAQs

We Here to Help.

FAQs

Get anything you want to know about us and our product. Can’t find the answer you are looking for? Please chat to our friendly team.

Product Attributes

Testing and Performance

Compatibility and Customization

Service and Warranty

What We Do.

Tailored to Perfection: G·SAI’s Process

We transform your performance needs into precision-engineered shock absorbers, ensuring exceptional durability and control through a seamless four-step customization process.

Requirement Consultation

Share your vehicle specifications, driving conditions, and performance goals, including damping force, spring rate, and material preferences.

Technical Design

Our engineers develop a customized shock absorber solution, optimizing internal structures, valve settings, and adjustability to meet your exact needs.

Precision Manufacturing

With advanced CNC machining and strict quality control, we produce shock absorbers that deliver superior durability and consistent performance.

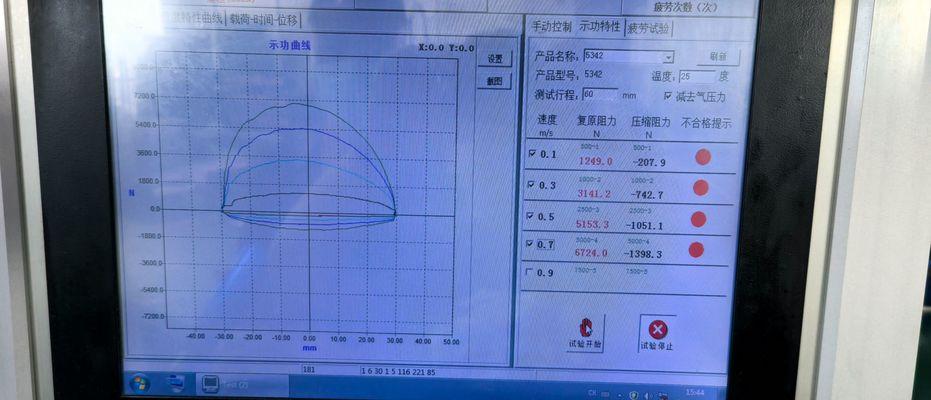

Testing & Certification

Each shock absorber undergoes rigorous testing, including durability, performance, and real-world simulations, ensuring reliability in off-road, racing, and extreme environments.

Chat With Us.

Ask For Other Question?

If you can’t find the answer in our FAQ, feel free to leave us a message. Our team will get back to you shortly with expert guidance.

Wait a moment.

Next Step

Swift Response & Technical Consultation

Our team promptly acknowledges your inquiry, discussing your vehicle specifications, driving conditions, and performance needs to ensure a tailored solution from the start.

Tailored Solution & Transparent Quotation

We provide a detailed proposal outlining shock absorber specifications, customization options, and pricing, ensuring full transparency at every step.

Smooth Collaboration & Finalization

Once you approve the proposal, we finalize technical details, confirm timelines, and initiate the precision manufacturing process, keeping you updated throughout.